Water vapor from compressed air is eliminated using an air dryer. Numerous industrial and commercial establishments frequently contain compressed air dryers. Unfortunately, air compression collects pollutants from the atmosphere, such as water vapor and oils. Read More…

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized coating...

The Onix Corporation is a leader in the dryer industry, specializing in rotary dryer & wood combustion systems, dryer control systems, & air pollution control systems. Other areas of expertise are wood fired boilers & industrial consulting on existing rotary dryers. All our equipment is industrial duty 24/7 equipment & carries a hostile environment rating, UL listing & a 3-year warranty.

Dri-Air Industries' expertise is in plastic drying technology. The plastic drying systems we offer problem solve for drying plastic resins, mixing and blending. Our product line includes industrial dryers, desiccant air dryers and hot air dryers. Newly offered is our micro dryer for micro molding machines.

BTU International is a global supplier/manufacturer of thermal processing solutions. Combining our engineering expertise with our acquisition of Radiant Technology Corporation’s product line, we have created the Rapid Thermal Processing (RTP) line of furnaces, specifically designed for solar cell applications such as contact drying/firing and metalization.

More Air Dryer Manufacturers

Compressed air users may experience several operational issues due to excessive water in the gaseous or liquid state. These include fouling processes and products, freezing of exterior airlines, piping and equipment corrosion, malfunctioning pneumatic process control instruments, and more.

Working Principle of Air Dryers

Each air dryer uses a different process to remove the water vapor from the air they are meant to dry. The term "dew point" refers to measuring how dry the air is after processing. The water vapor in the air decreases as the dew point temperature rises.

Different Types of Air Dryers

There are several different styles of compressed air dryers. The dew point frequently identifies these styles’ performance characteristics.

- Refrigerated Dryers

- Deliquescent Dryers

- Regenerative Desiccant Dryers

- Membrane Dryers

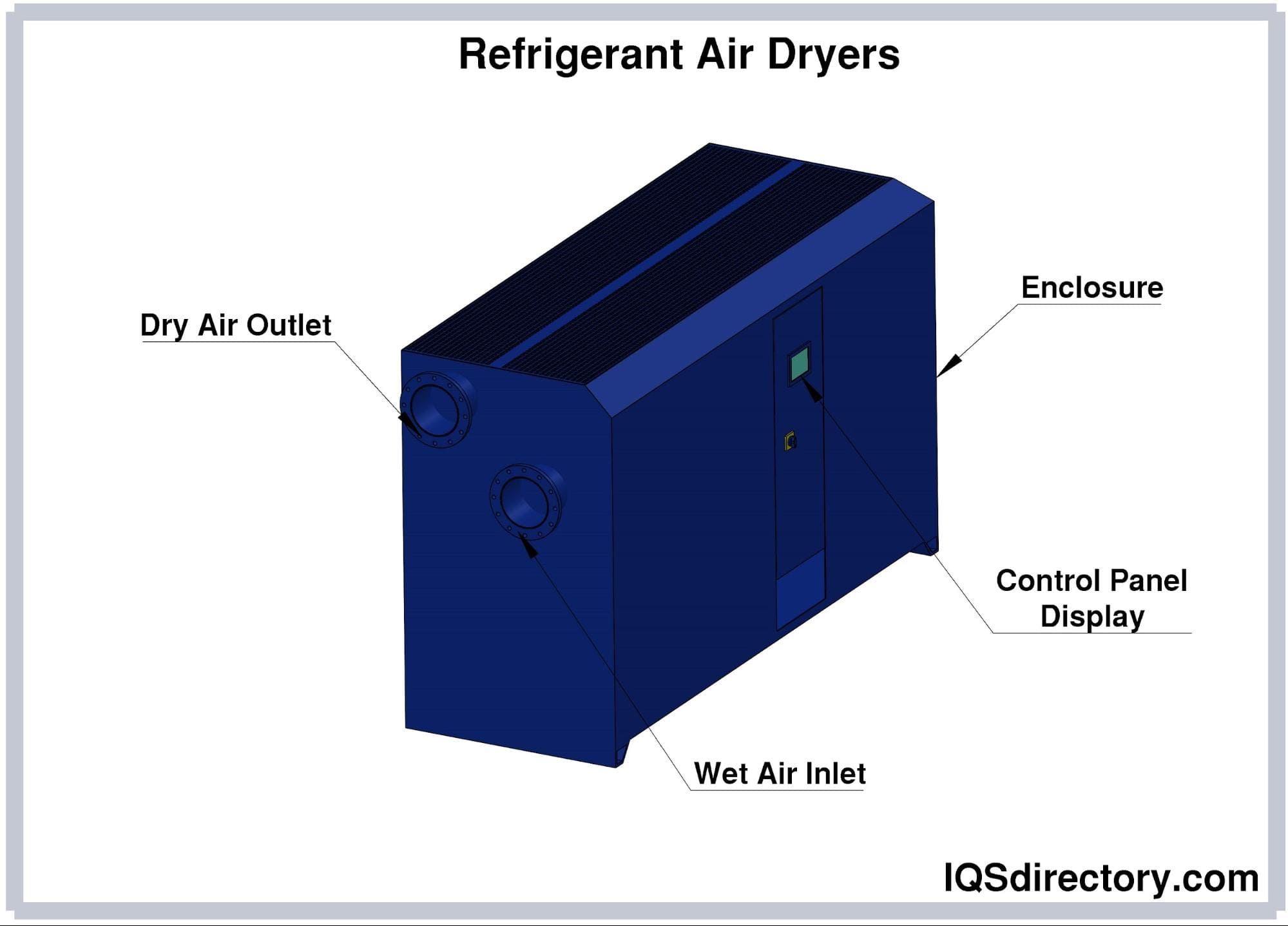

Refrigerated Dryers

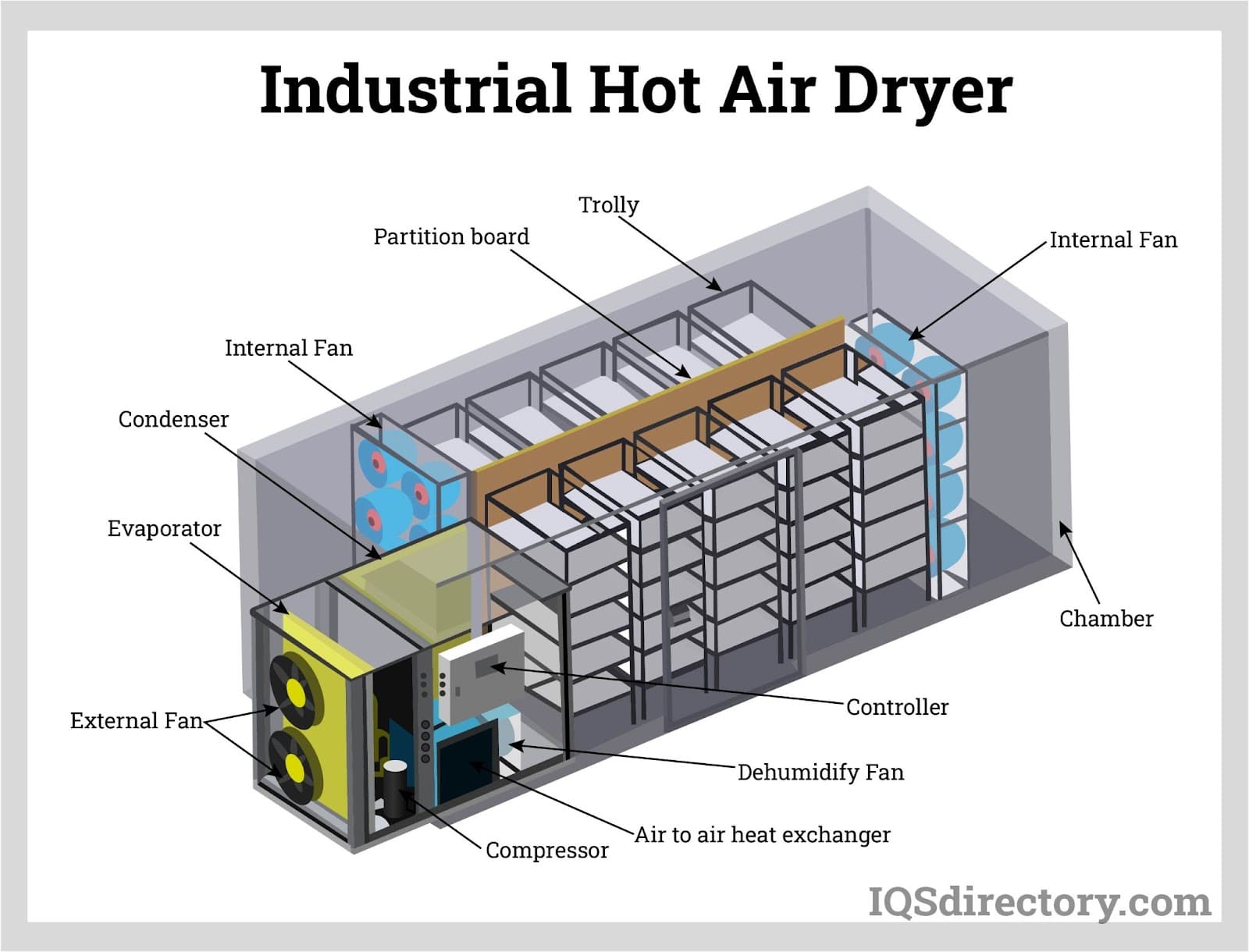

Two heat exchangers are used in refrigeration dryers, one for air-to-air and the other for air-to-refrigeration. The purpose of using two heat exchangers is to lower the size of the compressor needed by cooling the hot incoming air with the cold departing air. At the same time, the rising temperature of the outgoing air stops condensation from happening again.

A huge mass takes much longer to cool when the refrigeration compressor is running; therefore, the compressor runs longer and stays OFF longer. The average operating range for these machines' dew points is between 35 and 40 °F. These machines supply compressed air with lower dew points if the optional "cold coalescing filter" is chosen.

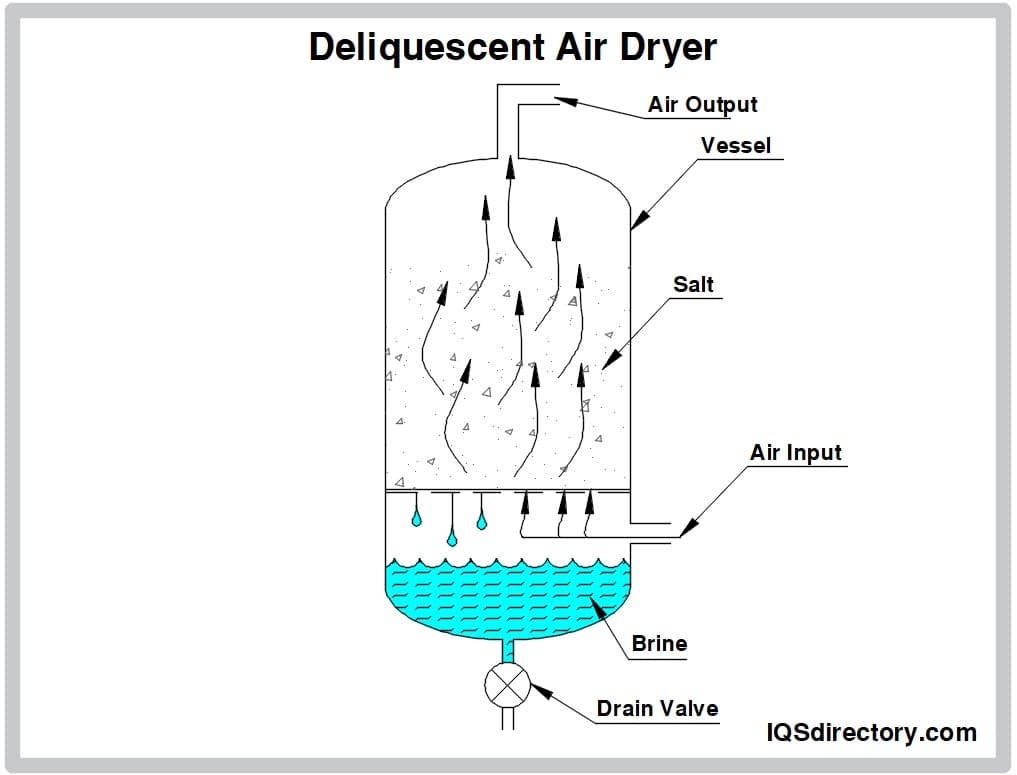

Deliquescent Dryers

A deliquescent dryer consists of a pressure vessel filled with a hygroscopic material that collects water vapor. At the bottom of the pressure vessel, the media gradually dissolves or deliquesces to produce a solution. Regular media replacement and liquid draining from the vessel are required. Typically, the media comes in tablet or briquette form.

Deliquescent dryers operate without electricity and do not have any moving parts. Therefore, common applications frequently include hazardous, mobile, or remote work environments. In addition, deliquescent dryers are used to remove water vapor from waste gases like digester gas, landfill gas, natural gas, and compressed air. The performance of a deliquescent dryer is significantly influenced by the temperature of the air or gas being treated; lower temperatures produce higher performance, as shown by the exit dew point.

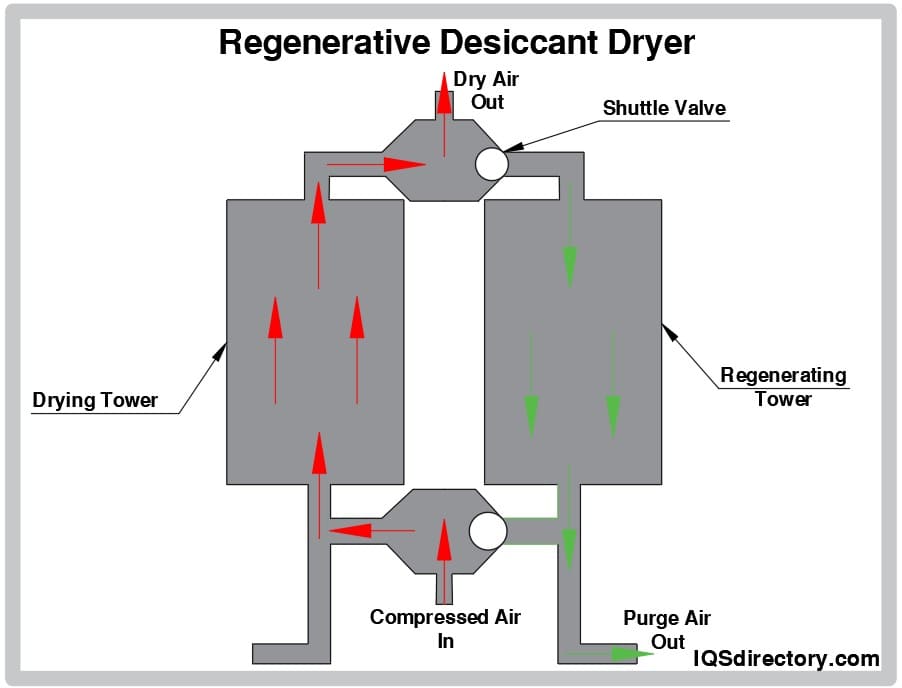

Regenerative Desiccant Dryers

Regenerative dryers, twin tower dryers, and absorption dryers are some of the more popular names for desiccant dryers. A pressure vessel containing a porous media, such as activated alumina, silica gel, molecular sieve, or another desiccant substance, is used to transmit compressed air. The desiccant can lower the air's water vapor's dew point to or below 40 °C (104 °F) and indicates that unless the air is cooled to 40 °C (104 °F), water will not condense (deposit).

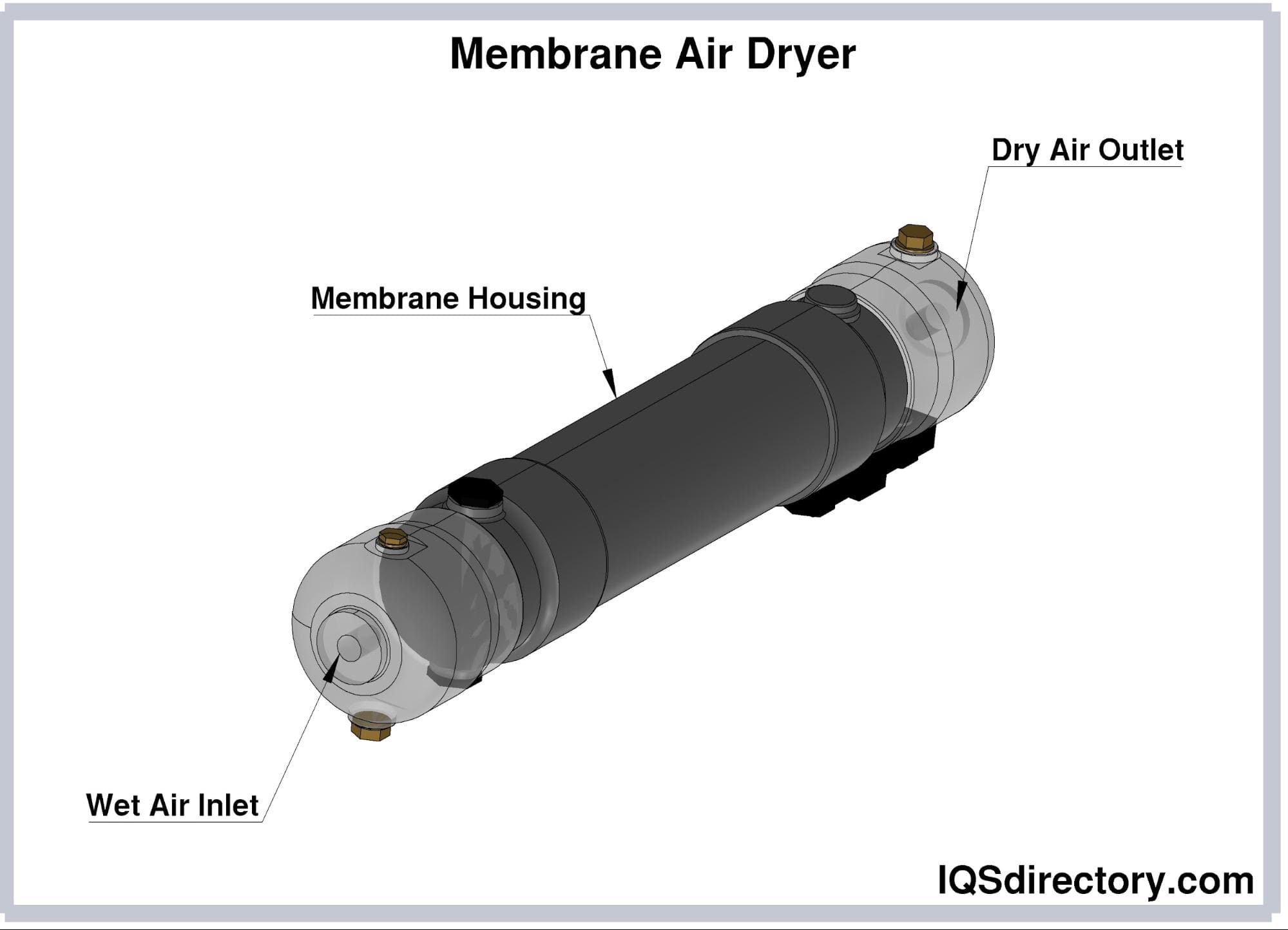

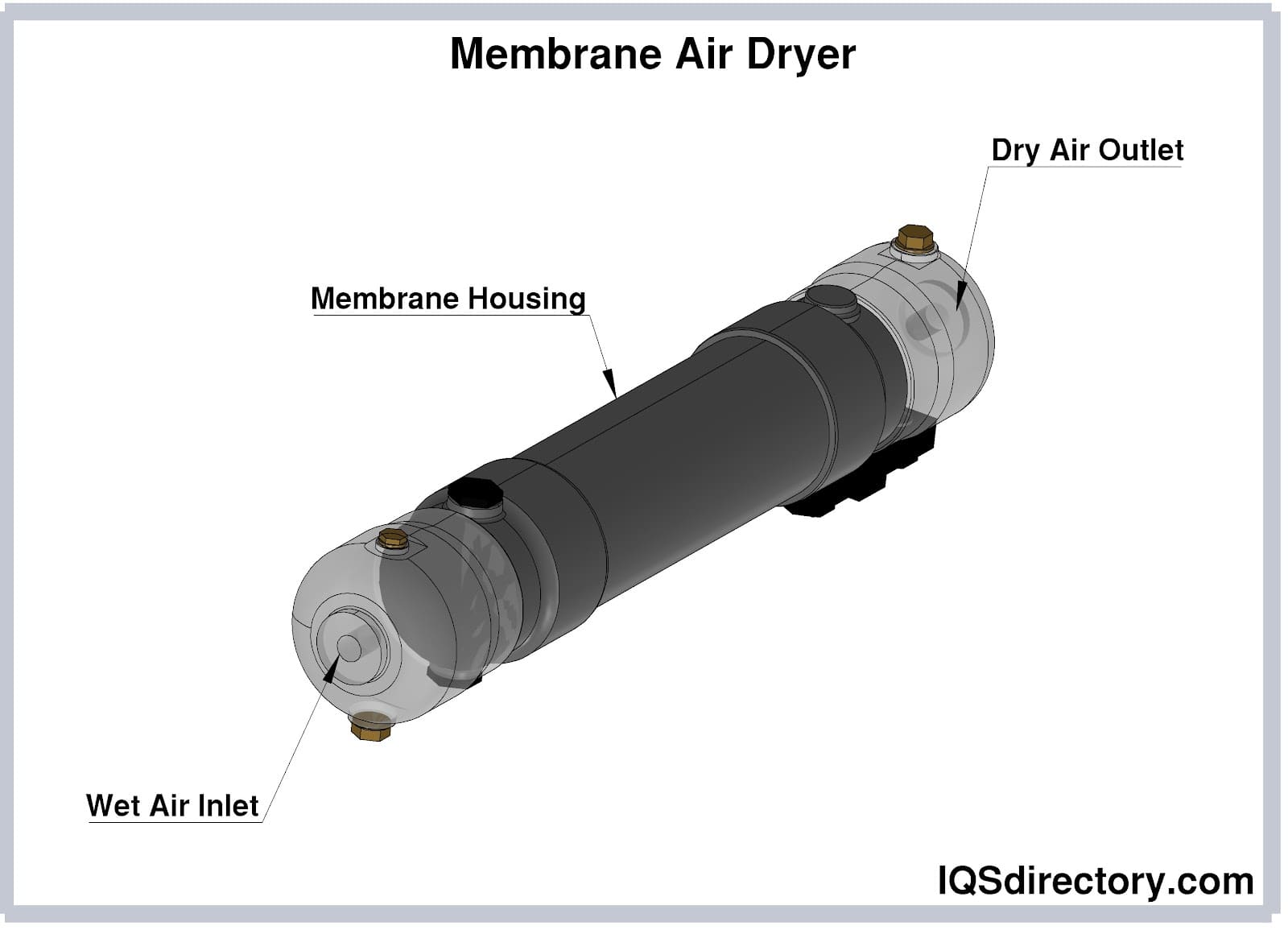

Membrane Dryers

Membrane dryers are devices that dry compressed air using a dehumidification membrane by compressing filtered air to remove liquid water, oil, and particulates. The water vapor-filled air travels through the membrane bundle's hollow fiber center bore. A tiny quantity of the dry air product is also directed along the fibers' exterior surface to remove the water vapor that has pierced the membrane. Then, clean, dry air is delivered to the application while the moisture-filled sweep gas is vented to the atmosphere. Membrane air dryers operate without power and are silent and dependable.

Membrane air dryers decrease the incoming dew point. The majority of dryers contain specifications for challenging air dew points and pressure. Therefore, the output dew point is even lower than required if the inlet dew point is lower than the specified challenge air. Pressure also has an impact. The exit dew point will decrease if the pressure exceeds the rated standard. The extended residence time the air spends inside the membrane causes this decrease in the output dew point. The kind of membrane will determine how much it has improved.

Applications of Air Dryers

Materials Manufacturing

To provide and maintain an optimal production environment, dried compressed air is frequently needed for material manufacturing procedures like lathe chucks, pressure cleaning of mechanical parts, and component cooling.

Oil and Gas Recovery

Applications of air dryers in oil and gas recovery include:

- Operation of drill rig controls

- Oil and gas transportation

- Driving pneumatic systems

- High-pressure enhanced oil recovery

Pharmaceutics

In the pharmaceutical sector, air dryers are utilized in various processes, such as tablet manufacture, fermentation, instrument air drying, drug drying, and packaging, which all need to dry compressed air.

Fabric Synthesis

High volumes of compressed air are needed in the textile production industries for air knives, air blow guns, lifting with pneumatic systems, and cooling equipment components.

Food and Beverage Production

High-quality food and drink are produced, packaged, and preserved using dried compressed air.

Advantages of Compressed Air Dryers

- Lengthening of piping, equipment, and tool lifespans

- Equipment maintenance cost savings

- Prevention of equipment corrosion

- Effective filtration of compressed air to remove particulates, water vapor, and other moisture content

Disadvantages of Air Dryers

- Higher maintenance cost

- Requires high initial investment

- Air filtering is required to stop the degradation of desiccant caused by suspended oils.

Choosing the Right Air Dryer Supplier

To ensure you have the most positive outcome when purchasing an air dryer from an air dryer supplier, it is important to compare several companies using our directory of air dryer suppliers. Each air dryer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each air dryer business website using our proprietary website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple air dryer businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services