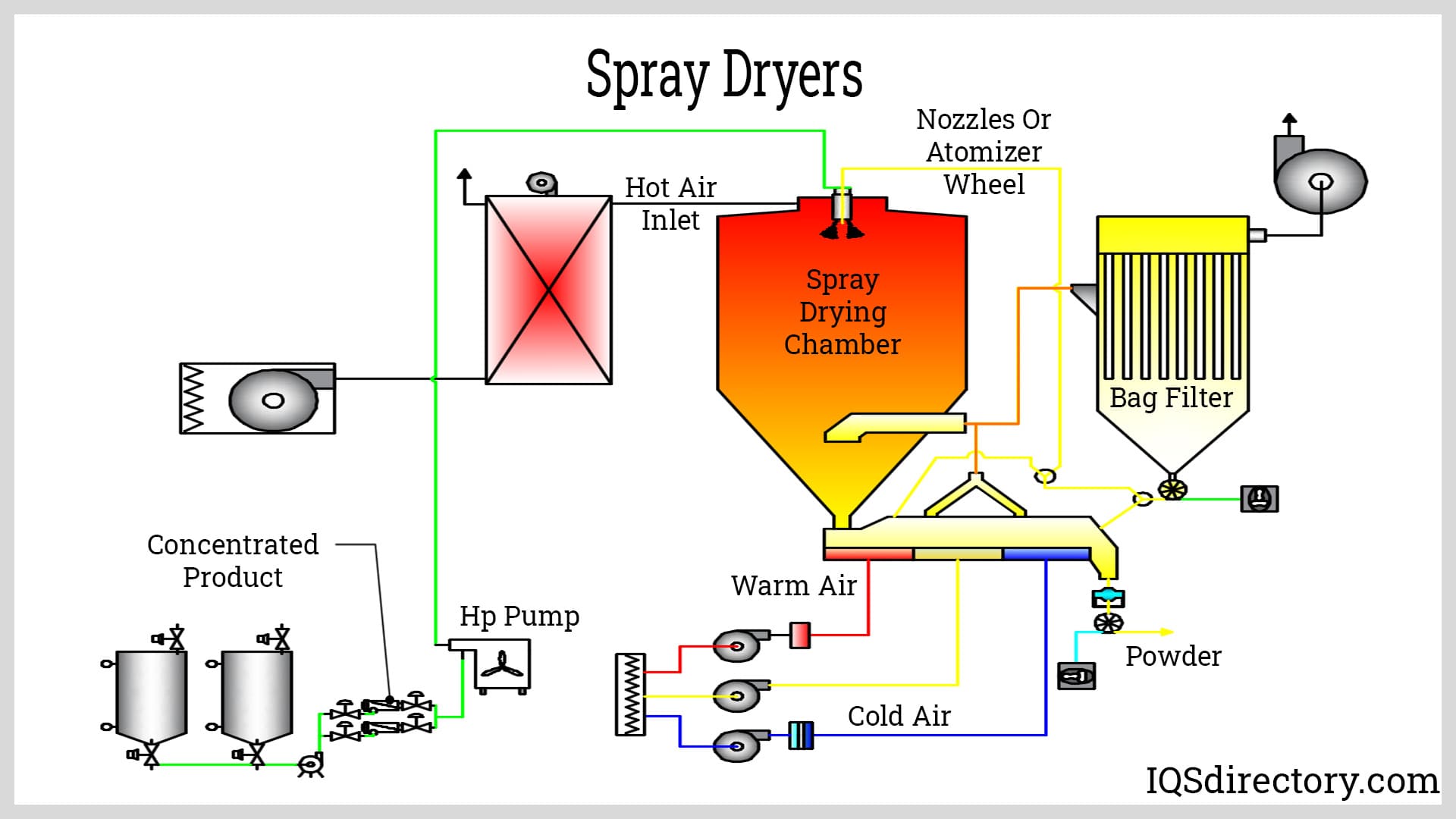

Spray drying is the process of atomization or changing a liquid or slurry into a powder by heating a gas. This technology is mostly applied to thermally sensitive materials, such as food pharmaceuticals, where consistently fine particles are desired. The spray drying process feedstock should have a standard solid content, viscosity, and density Read More…

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized coating...

The Onix Corporation is a leader in the dryer industry, specializing in rotary dryer & wood combustion systems, dryer control systems, & air pollution control systems. Other areas of expertise are wood fired boilers & industrial consulting on existing rotary dryers. All our equipment is industrial duty 24/7 equipment & carries a hostile environment rating, UL listing & a 3-year warranty.

Dri-Air Industries' expertise is in plastic drying technology. The plastic drying systems we offer problem solve for drying plastic resins, mixing and blending. Our product line includes industrial dryers, desiccant air dryers and hot air dryers. Newly offered is our micro dryer for micro molding machines.

BTU International is a global supplier/manufacturer of thermal processing solutions. Combining our engineering expertise with our acquisition of Radiant Technology Corporation’s product line, we have created the Rapid Thermal Processing (RTP) line of furnaces, specifically designed for solar cell applications such as contact drying/firing and metalization.

More Spray Dryer Manufacturers

Types of Spray Dryers

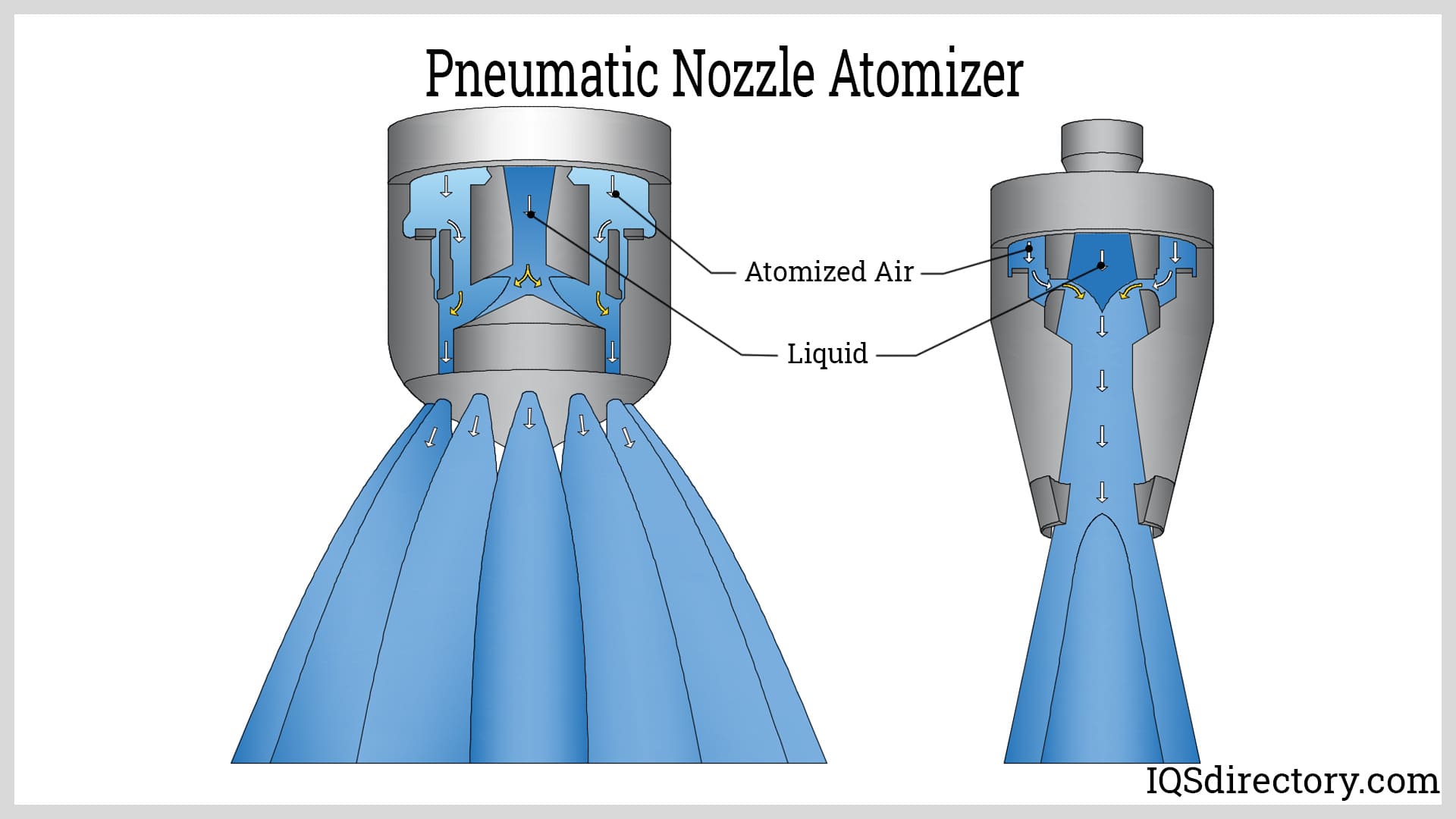

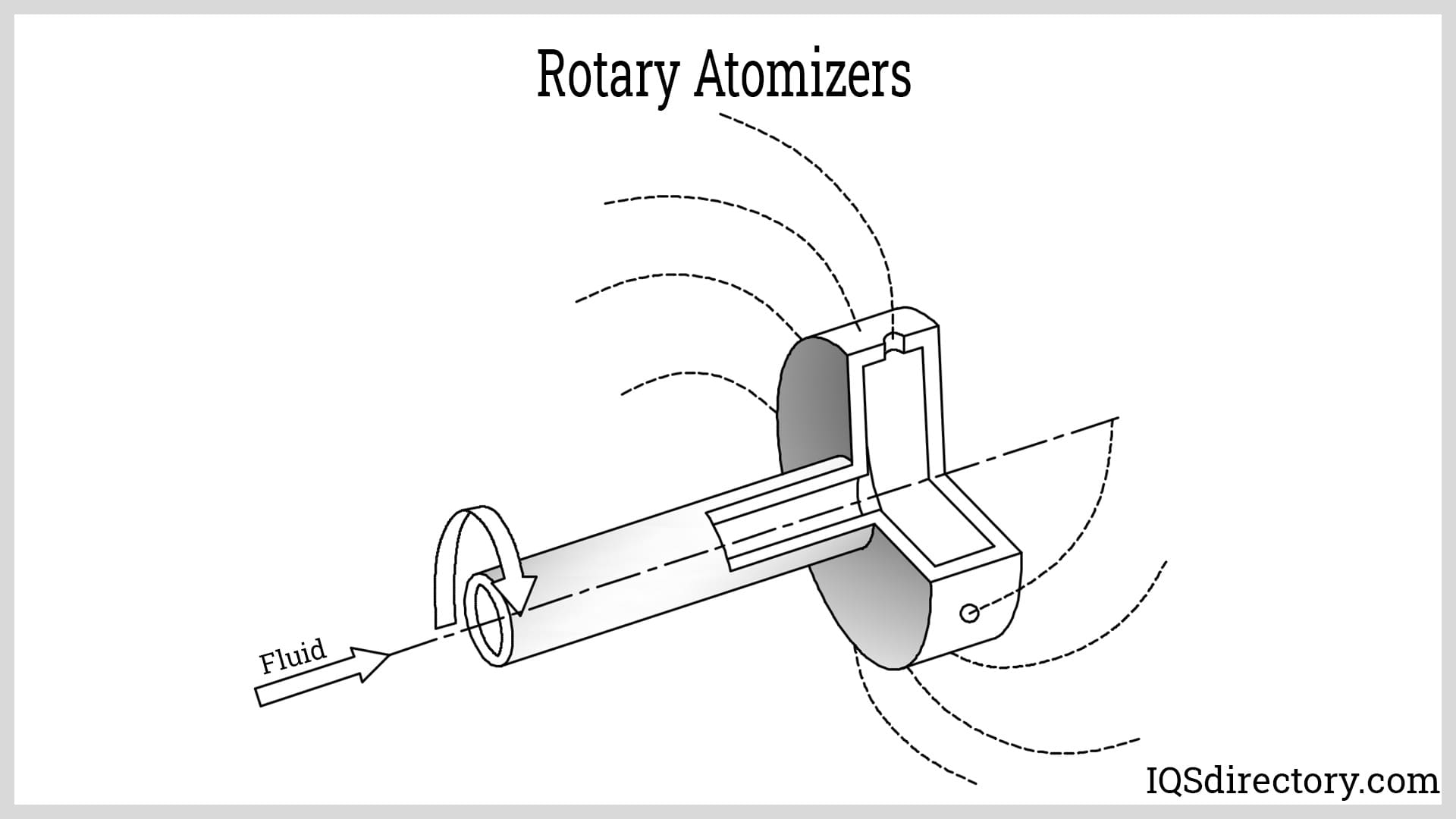

The principle of operation and design of nozzles/atomizers distinguishes spray dryers. A nozzle is often used to make the droplets as tiny as possible, optimizing heat transmission and water vaporization rate. Nozzles are classified into two types: high-pressure single-fluid nozzles and two-fluid nozzles. The first fluid in a two-fluid nozzle is the liquid that will be dried, while the second is a compressed gas. Based on the type of atomization energy, spray dryers can be further distinguished into the following:

- Rotary atomizers: Atomization energy is centrifugal. The feedstock solution is driven to the center of the horizontal wheel or disk in rotary atomizers. A centrifugal force is produced at this point, accelerating the feed solution to the perimeter and generating a spray of droplets. It has the advantage of handling high feed rates without clogging, particle production of homogeneous size, low-pressure running, and high efficiency. However, rotary atomizers are expensive, incompatible with viscous feed, and need help to employ a horizontal spray dryer chamber and the undersized spray dryer chambers.

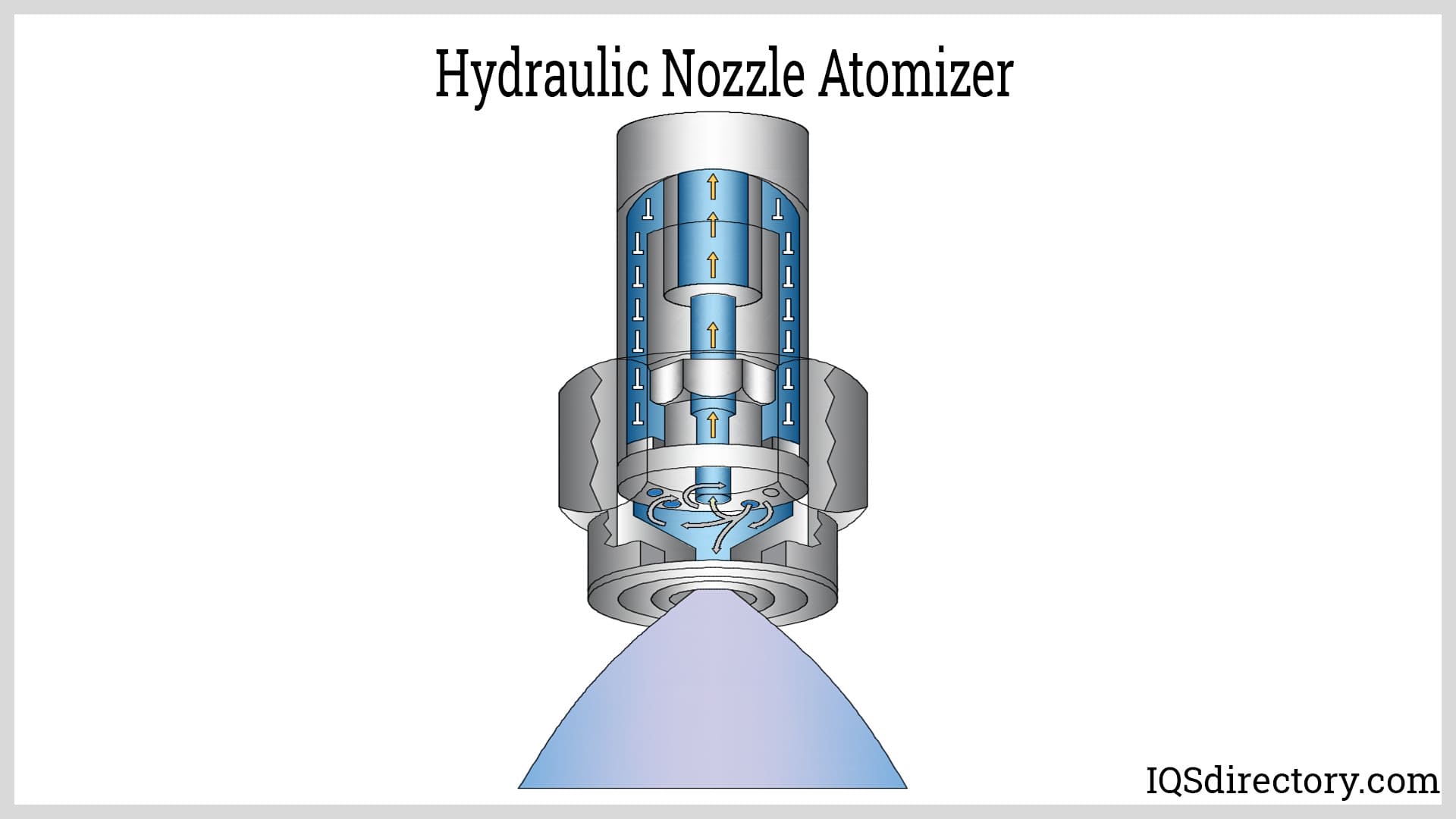

- Hydraulic nozzle atomizers: Pressure is the source of atomization energy. The operation concept of hydraulic nozzles, also known as one-fluid nozzles, consists of the conduction of the feed solution under pressure through a gradually decreasing diameter conduit. The fluid emerges at high velocity through a tiny nozzle orifice (typically 0.4 to 4 mm in diameter) while simultaneously losing pressure, undergoing atomization, and disintegrating into droplets. They have the advantage of having relatively low-cost particle synthesis with less occluded air (i.e., greater density particle manufacturing) and allowing for small drying chambers. However, high viscous feed is not recommended; high feed rates result in coarser and less homogeneous sprays (i.e., broad particle size distribution).

- Pneumatic nozzle atomizers: These atomizers are also known as an internal or external two-fluid nozzle, where kinetic energy provides the atomization energy. Pneumatic atomizers have better particle size control than a hydraulic nozzle, are more effective for high viscosity feeds, and are appropriate for laboratory scale due to the tiny drying chamber required. However, this type of atomizer is associated with high operating costs due to the requirement for large amounts of compressed gas for atomization, particle production with high occluded air, and downstream turbulence.

Operational Principle of Spray Dryers

Spray dryers separate the solute as a solid and the solvent as a vapor from a liquid stream. The solid is generally collected in a drum or cyclone. The liquid input stream vaporizes after being sprayed into a hot vapor stream. A solid shape as the droplets' moisture quickly evaporates. Making the droplets as tiny as possible with a nozzle will increase heat transmission and the water vaporization rate. Adjusting the process temperature also determines the moisture content in the final powder. The powdered mix is collected, after which the gas is re-circulated. The process layout can include the following,

- Open cycle layout

- Closed cycle layout

- Semi-closed (standard) layout

- Semi-closed (self-energizing) layout

- Two stage layout

- Combination layout

Spray Dryer Applications

- For amorphous solid dispensation, pharmaceuticals are formed into a polymer matrix that better diffuses into the patient's body using spray dryers. An example of a pharmaceutical produced this way is antibiotics. Spray dryers are also used in the biomedical field for nasal administration of medicines, vaccine development, and antibiotic injections.

- The food industry uses spray drying to dehydrate food substances and products, for example, powdered milk, colorings, coffee, spices, etc.

Advantages of Spray Drying

- It consumes little time.

- The process is ongoing, hence not labor intensive.

- Spray drying does not contaminate substances; sterilized substances can be produced.

- Applicable as a preservation method

- Particle size is controlled and uniform.

- The end product is concentrated and soluble.

- Applicable to solutions and emulsions

Disadvantages of Spray Drying

- Equipment is costly and cumbersome.

- It provides low thermal efficiency since large volumes of air tend to pass through without catching any particles.

- Equipment needs consistent cleaning to avoid contamination.

- It cannot be used to dehydrate solid substances.

- Solid products can result in a fire hazard if deposited in the drying chamber.

Conclusion

Spray dryers are devices that atomize or facilitate the production of a solid powder by rapidly drying liquid, slurry, or emulsion using hot gas. The nature of the final product obtained after drying in a spray dryer is determined by the spray dryer's design and operation, as well as the physicochemical properties of the feed.

Choosing the Correct Spray Dryer Company

For the most beneficial outcome when purchasing a spray dryer from a spray dryer company, it is important to compare several companies using our directory of spray dryer suppliers. Each spray dryer supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or request a quote. Review each spray dryer business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple spray dryer businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services