A food dryer is a device used to remove moisture from food without over-drying it. Food dryers offer complete control of temperature during food drying. Therefore, they can create dried foods at low temperatures, considered a raw food. Read More…

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized coating...

The Onix Corporation is a leader in the dryer industry, specializing in rotary dryer & wood combustion systems, dryer control systems, & air pollution control systems. Other areas of expertise are wood fired boilers & industrial consulting on existing rotary dryers. All our equipment is industrial duty 24/7 equipment & carries a hostile environment rating, UL listing & a 3-year warranty.

Dri-Air Industries' expertise is in plastic drying technology. The plastic drying systems we offer problem solve for drying plastic resins, mixing and blending. Our product line includes industrial dryers, desiccant air dryers and hot air dryers. Newly offered is our micro dryer for micro molding machines.

BTU International is a global supplier/manufacturer of thermal processing solutions. Combining our engineering expertise with our acquisition of Radiant Technology Corporation’s product line, we have created the Rapid Thermal Processing (RTP) line of furnaces, specifically designed for solar cell applications such as contact drying/firing and metalization.

More Food Dryer Manufacturers

Raw food has many health benefits. For example, it is said that food dryers preserve the living nutrients and enzymes in vegetables and fruits, unlike the food created by the heating process, which is said to deplete or eliminate these components from food.

Types of Food Dryers

Food dryers come in different types and sizes depending on the purpose.

Tray Dryers

This type of food dryer functions and allows batch operations. Tray dryers consist of chambers for holding the products. Heating is achieved by an air current that circulates across the trays, by radiation from heated surfaces, or by conduction from heated shelves on which the trays lie. Most tray dryers utilize air as a heat source. The air removes the moist vapors.

The important or valuable aspect behind this process is the circulation of hot air through fans distributing hot air at a rate of two to five meters per second. Therefore, tray dryers are more suitable for small production rates.

Tunnel Dryers

Tunnel dryers comprise a family of dryers that utilize the continuous drying process. The food travels in a compartment shaped like a tunnel in which hot air circulates in these dryers. In most cases, tunnel dryers utilize air for drying the food material.

Trucks (in this case, a generic term for a wheeled vehicle used for moving heavy items) pulling stacks of trays pass through lengthy tunnels that serve as tunnel dryers, either moving with or against a stream of drying air. The material to dry is uniformly distributed on the trays. Wet vegetable trays typically have a payload of 10 to 30 kilograms (roughly 22 to 66 pounds) per square meter (a meter is a little larger than a yard). A vehicle bringing wet material enters at one end of the tunnel, while a truck bringing dehydrated material emerges at the other.

The trucks move automatically or manually, for example, with chains, depending on the size of the trucks and tunnel. Tunnel dryers can work in a co-current, counter-current, or mixed-current mode depending on the relative direction of the air and the trucks moving.

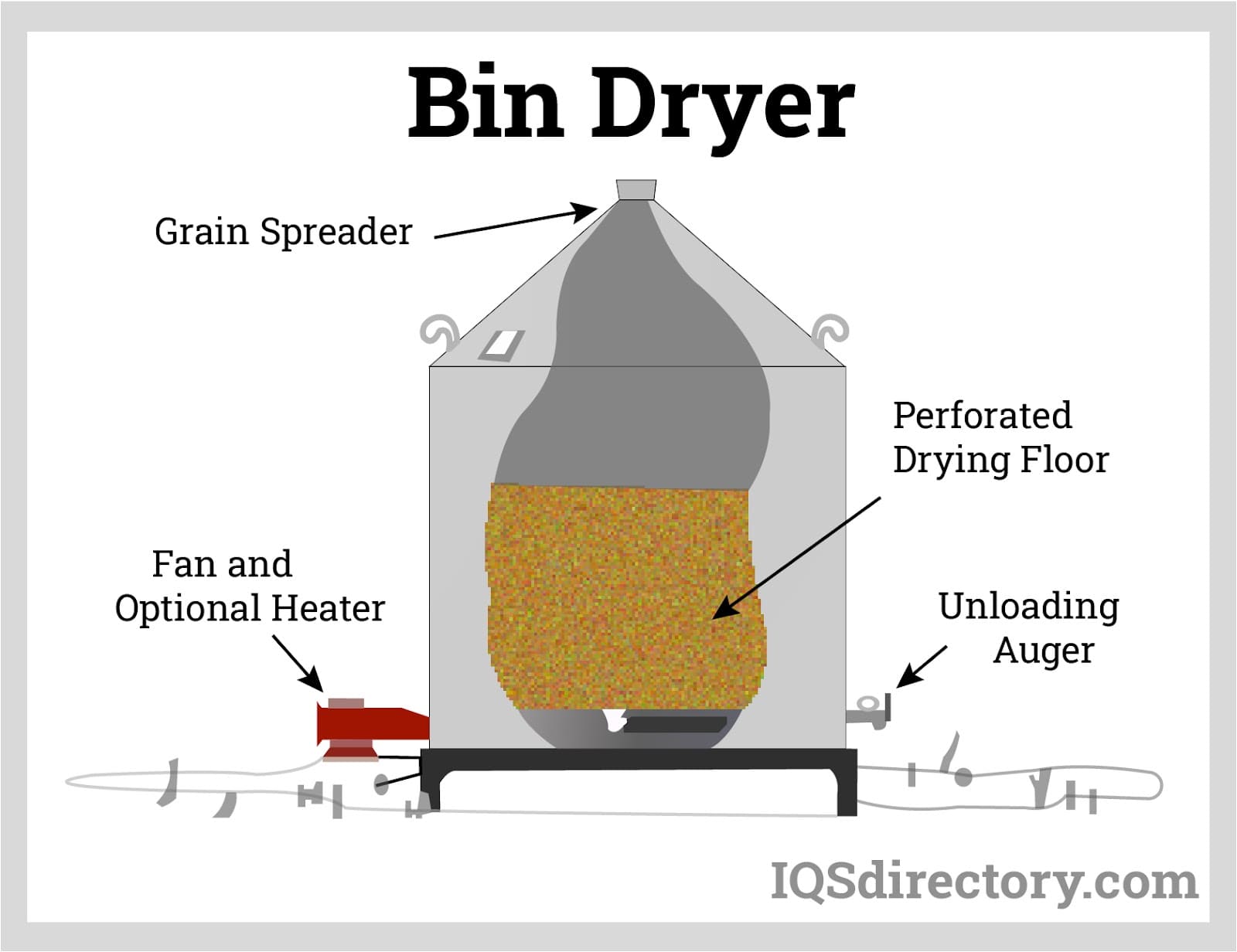

Bin Dryers

Bin dryers are used to dry products with relatively low moisture content and are robust enough to resist the stress of being crushed, like squash. Using hot air forced up via a wire-mesh bottom, the bins are large, substantially cylindrical, or rectangular containers.

The dryers are frequently employed as the final phase because of the sluggish air circulation. Bin dryers work in batch mode. Because there are a lot of goods stacked up, moisture levels can balance out, and these dryers can serve as a barrier between other dryers and the packing of the food items.

Belt Dryers

The belt-drying method spreads wet material on a conveyor belt or horizontal mesh within a drying tunnel. Different zones may be created within the drying tunnel. An air heating and circulation system are installed in each zone to ensure air passes through and over the material.

Hot, dry air is blasted through the product layer (from above and then below, alternately) when the raw material conveyor passes through the tunnel. The product layer is dried on all sides, producing an evenly-dry final product. In many cases, the belt is moving, but in some designs, the belt will be stationary, and the transportation of the food material through the tunnel is done by scrapers moving alongside the belt.

Freeze Dryers

Freeze dryers hold food material on belts or shelves within a chamber that is under a high vacuum. To guarantee that sublimation (the conversion of a solid to a gaseous state without becoming a liquid), rather than melting, takes place, the freeze dryer cools the material below its triple point (the combination of temperature and pressure where an item can simultaneously exist as a solid, liquid, and gas). This keeps the material's physical shape intact.

The food is often frozen before it is loaded into the dryer. Heat transfer to the food occurs through the conduction process or radiation. A vacuum pump is then used to remove the vapor and condense it.

Applications of Food Dryers

The most common uses of food dryers are listed below:

- Food dryers are used to remove moisture from food.

- They are used to reduce the size of the food for storage purposes.

- Food dryers are used to dry foods to increase their shelf life.

- Food dryers are used at home and in food processing industries.

Benefits of Food Dryers

The use of food dryers provides the following benefits:

Dehydrated Foods Have a Great Taste

When a food dryer removes moisture from foods like meats, vegetables, and fruits, it creates naturally concentrated and delicious-tasting food.

Reduced Wastage of Food Through Extended Shelf Life

When using a food dryer, there is reduced food waste. When fruits and vegetables are dried using a food dryer, their shelf life is extended to 2 years.

Create Healthy and 100% Natural Foods

Food drying needs only one ingredient, which is the food that is being dried. Therefore, the product is 100% natural and retains all the minerals and fiber of the whole fruit.

Cost Savings

Since processed foods can be expensive, using a food dryer can help in saving a lot of money. With a food dryer, there is no need to buy processed and dehydrated foods since all that can be done at home. Food dryers are also cost-effective to run.

Efficient Storing

Dried foods occupy less space than their original form could occupy. Furthermore, they do not need the ongoing electrical drain of a freezer or refrigerator. The significant reduction in the size of dried foods means that a lot of preserved food can be fit into a small area. This is especially an ideal solution for camping and large families.

Portability

Food dryers produce compact foods that are also lightweight. Since healthy foods can be expensive, perfectly healthy snacks for lunch boxes can be created by dehydrating foods at home.

Flexible and Versatile

Food dryers offer more flexibility in drying any food. These machines can also run for hours over several days.

Simple and Easy to Use

These machines are easy to use. The temperatures of the food dryer can be set so low that it will be impossible to over-dry the food.

Disadvantages Associated With Using Food Dryers

Some of the disadvantages of using food dryers include the following:

Time Commitment of Dehydration

Dehydrating food requires a time commitment; once the process starts, there's no room to stop or pause. There's also a need to note that fresh foods are always the best because air and other elements influence how enzymes behave.

Vegetables should be washed, chilled, and preserved to retain their best flavor as soon as they are harvested from the garden. Attracting mold and other bacterial organisms is also possible if the procedure is interrupted during the dehydration process. Thus, completing each task with minimum to zero delays is critical.

Vitamins A and C are Decreased

Food dehydrators lessen part of the vitamin A and C content in fruits and vegetables is a drawback. This is an inevitable result of the drying and dehydrating process. Methods have been devised to compensate for this loss, such as exposing fruits to sulfur before drying.

Making Taste and Appearance Adjustments

This may be the most difficult obstacle to overcome when starting to eat dry foods. Foods that are dried at home in a food dehydrator possess a slightly different flavor and appearance than dried foods purchased from the store's snack section. Apples may appear darker, and the increased sweetness may be unexpected upon first taste.

However, many owners of food dehydrators prefer the appearance and flavor of their "home-cooked" food to that of store-bought food. It truly is just a question of getting used to something new and discovering which foods you prefer dried to which you insist upon being fresh for first-time dehydrator users.

Choosing the Right Food Dryer Supplier

To ensure the most productive outcome when purchasing a food dryer from a food dryer supplier, it is important to compare several companies using our directory of food dryer suppliers. Each food dryer supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the company for more information or request a quote. Review each business website using our patented website previewer for a better understanding of what each company specializes in. Then, use our simple RFQ form to contact multiple food dryer businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services