An industrial dryer is a device designed for simultaneously heating and withdrawing moisture from the surface of materials. Industrial dryers have various applications, including pharmaceutical, commercial, and industrial uses. Read More…

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized coating...

The Onix Corporation is a leader in the dryer industry, specializing in rotary dryer & wood combustion systems, dryer control systems, & air pollution control systems. Other areas of expertise are wood fired boilers & industrial consulting on existing rotary dryers. All our equipment is industrial duty 24/7 equipment & carries a hostile environment rating, UL listing & a 3-year warranty.

Dri-Air Industries' expertise is in plastic drying technology. The plastic drying systems we offer problem solve for drying plastic resins, mixing and blending. Our product line includes industrial dryers, desiccant air dryers and hot air dryers. Newly offered is our micro dryer for micro molding machines.

BTU International is a global supplier/manufacturer of thermal processing solutions. Combining our engineering expertise with our acquisition of Radiant Technology Corporation’s product line, we have created the Rapid Thermal Processing (RTP) line of furnaces, specifically designed for solar cell applications such as contact drying/firing and metalization.

More Industrial Dryer Manufacturers

Industrial dryers are frequently employed as a setup in many different industrial processing applications. Their primary function is to eliminate or remove moisture, water, and other solvents from processed material. Since industrial dryers come in various forms and sizes with varying specifications, choosing a suitable dryer is essential for processing. In addition, industrial dryers should be carefully studied to avoid changing or impairing a material's physical, chemical, or biological properties.

The Working Principle of an Industrial Dryer

Industrial dryers use three-stage processes to handle batch operations. Manufacturers use a variety of dryers to complete high-quantity orders efficiently. Therefore, the right industrial dryer is required for each stage of the operation.

First, A sample or product is placed in an industrial dryer. Next, the product is heated to a specified temperature to draw moisture from the substrate of its surface. The material is then left immersed at a specified temperature level for a predetermined time interval. Afterward, the industrial dryer ventilates that heat. It then brings in cooler surrounding air to reduce the risk of the material reabsorbing moisture from the oven's interior during this cool-down process.

Whether a dryer uses air, infrared, or spray drying, the phrase "industrial dryers" refers to all dryers. Although there are certain commonalities, there is no one design or type of industrial dryer due to the variability of the processed items, processing requirements, or the materials used to construct the dryer. Because stainless steel is durable, hygienic, and corrosion-resistant, many dryers are constructed from it.

They frequently form rectangular or cylindrical tanks with numerous connections, apertures, gauges, and controls for input and output. While some work in batches, some may be continuous and use a conveyor belt to dry a continual flow of materials. The type of dryer and the material to be dried will determine the capacity. While some dryers might be designed to contain just one cubic foot, others can dry over 25,000 pounds per hour.

Dryers serve various purposes when working with chemicals, dairy products, fertilizers, cereals, minerals, paper, plastics, trash, and more. They are crucial for the pharmaceutical, food processing, manufacturing, water treatment, and paper sectors.

Most industrial dryers are bolted or welded together depending on the significance of the seams, the expected product, and any motion the dryer may experience. The three primary drying techniques cover a range of models that execute the operation in various ways. The most popular industrial dryers are air dryers. They directly expose substances to hot air, allowing moisture to evaporate and spread into the atmosphere, leaving a dry product behind.

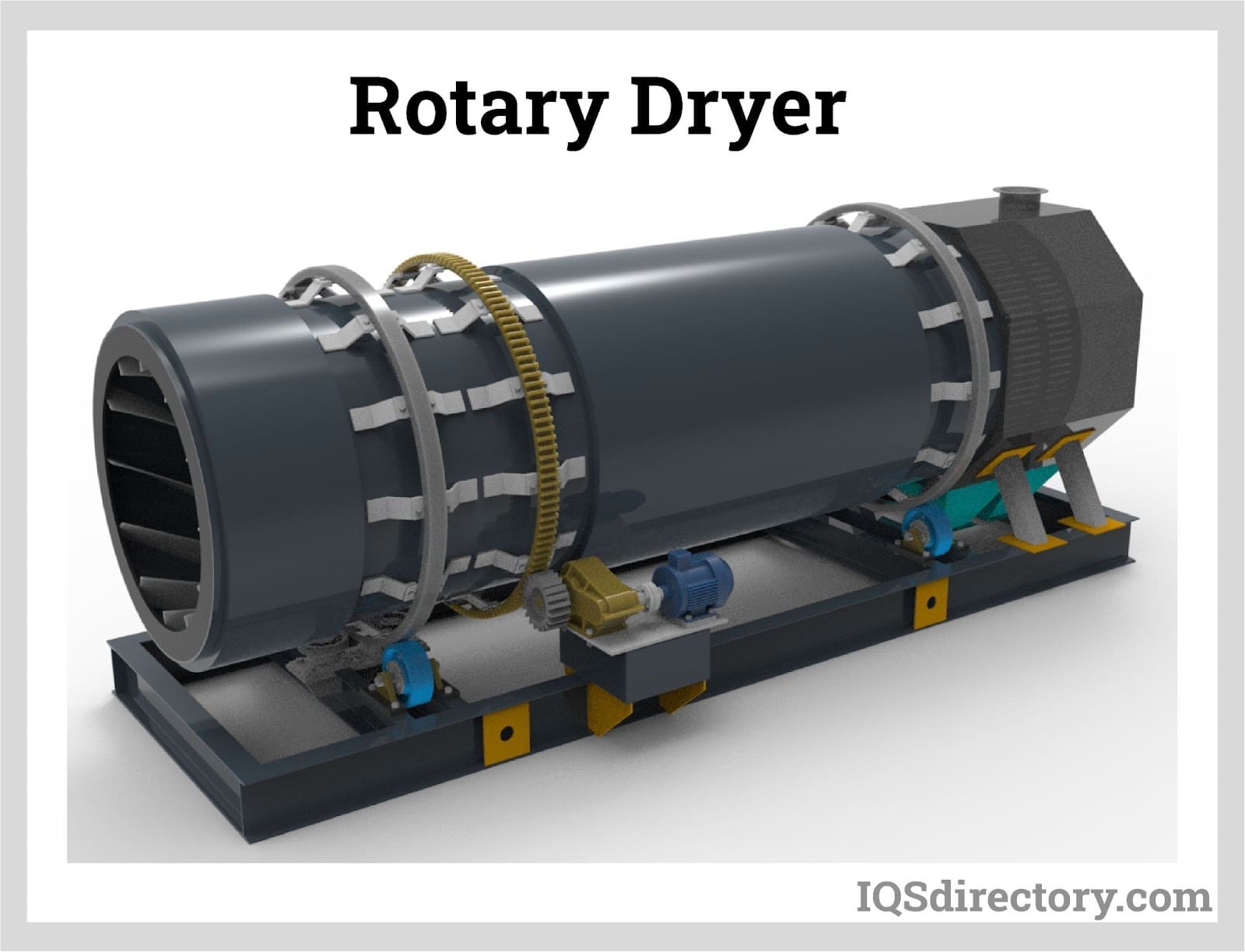

Although their designs differ, this category includes rotary, fluid bed, flash, and freeze dryers. While freeze-drying employs cold air and vacuums to thaw moisture and divert it away, flash-drying uses a brief, strong burst of heat to dry materials immediately. Rotary dryers are enormous drums that dry materials as they revolve and tumble them through the hot air trapped within; fluid bed dryers blast steam up through a perforated plate to make the solid substance act like a fluid.

Because the wavelength may be adjusted to the product's absorption rate to maximize energy efficiency and resources, infrared dryers rely on electromagnetic radiation from a specific wavelength segment to dry solid materials fast and without overheating them. Hot steam jets are used during spray drying to expose the material, which causes the moisture to evaporate and flash dry.

Types of Industrial Dryers

The different types of industrial dryers include:

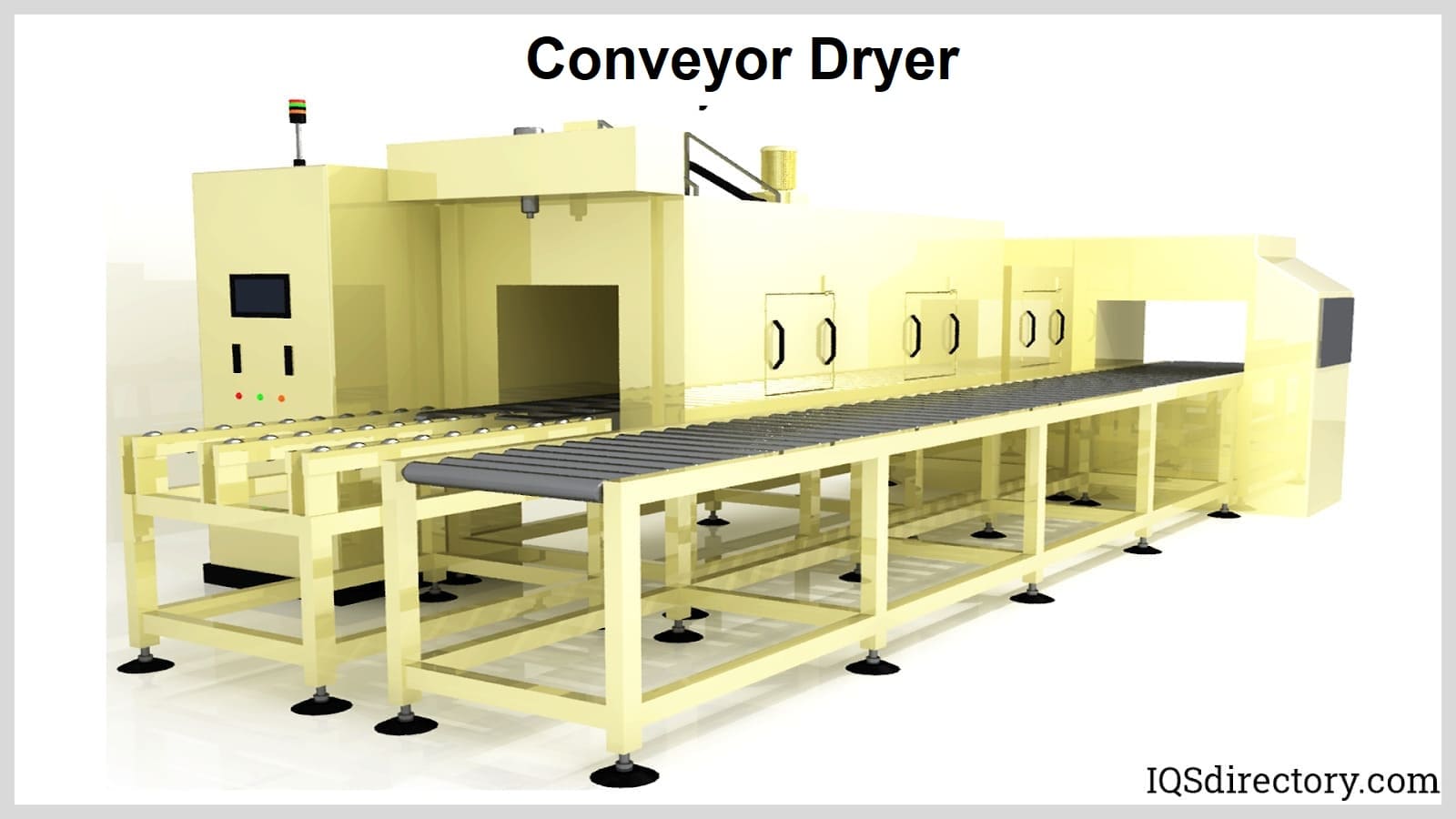

Conveyor Dryers

These types of industrial dryers are utilized in processes that continuous production of small as well as medium-sized products. Therefore, industrial dryers make a great choice if a factory employs automated mass production, as they perfectly fit many production lines.

Vacuum Dryers

Vacuum dryers are versatile and are most commonly used in engineering research. However, they are also used in other industries where drying in a low-pressure environment is required. They may even include a digital interface for monitoring purposes. The vacuum dryer will automate this digital interface to minimize oxidation.

Convection Dryers

Convection dryers rely on high temperatures for the gentle acceleration of the dehydration process. Therefore, they are ideal for aging, pre-heating, sterilization, baking, and thermal storage.

Rotary Dryers

Rotary dryers are mostly used in the metal manufacturing industry. They are quick at drying this material without oxidation. In addition, they feature an energy-efficient design. This design may interlace with other processes to help keep their operating costs low.

Flotation and Roll-Support Web Dryers

These dryers are used in web and fabric coating, textile manufacturing, and packaging. They feature a stable airflow and precise temperature control to increase overall efficiency.

Vertical Tower Dryers

Vertical tower industrial dryers make optimal use of space while adding an industrial drying oven to an operation. This operation helps reduce overall costs while simultaneously increasing the quality and turnaround time.

Applications of Industrial Dryers

The applications of industrial dryers include:

Degassing Epoxy Resins

Some epoxy materials can actively absorb moisture to the extent that companies shouldn't mix them during periods of high humidity. Industrial dryers are used for combating this material drawback. In addition, they are used for removing gas from epoxy resins that have developed air or moisture pockets within the mixture.

Electronics Manufacture

Industrial dryers are used in the electronics industry for treating electronic components like circuitry. These components are damaged by moisture; therefore, they must be dried. However, there is also the possibility of delamination or splitting apart printed circuits caused by liquid molecule exposure. As a result, it is critical to heat-treat these products.

Factory Environments

Industrial dryers are utilized to draw moisture in conveyor mechanisms, improve equipment service life, and prevent gradual mechanical corrosion.

Materials Testing

Material testing can determine the effects of long-term aging on different metals and polymers accurately with an industrial dryer.

Pharmaceutical

Industrial dryers are used in the pharmaceutical industry for sterilization and incubation purposes.

Benefits of Industrial Dryers

- Industrial dryers allow for a significant reduction in the time required for drying.

- Industrial dryers reduce product waste. As a consequence, associated economic losses are also reduced.

- Industrial dryers help in maximizing profits.

- These machines help in the electronic industry by improving the life span of components that can be damaged by liquid molecule exposure.

- Industrial dryers feature energy-efficient designs.

- These machines perfectly fit many lines of production.

- Industrial dryers improve the quality and the turnaround time of the materials and products they service.

Choosing the Correct Industrial Dryer Manufacturer

For the most positive outcome when purchasing an industrial dryer from an industrial dryer manufacturer, it is important to compare several companies using our directory of industrial dryer manufacturers. Each industrial dryer manufacturer has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial dryer business website using our proprietary website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple industrial dryer companies with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services