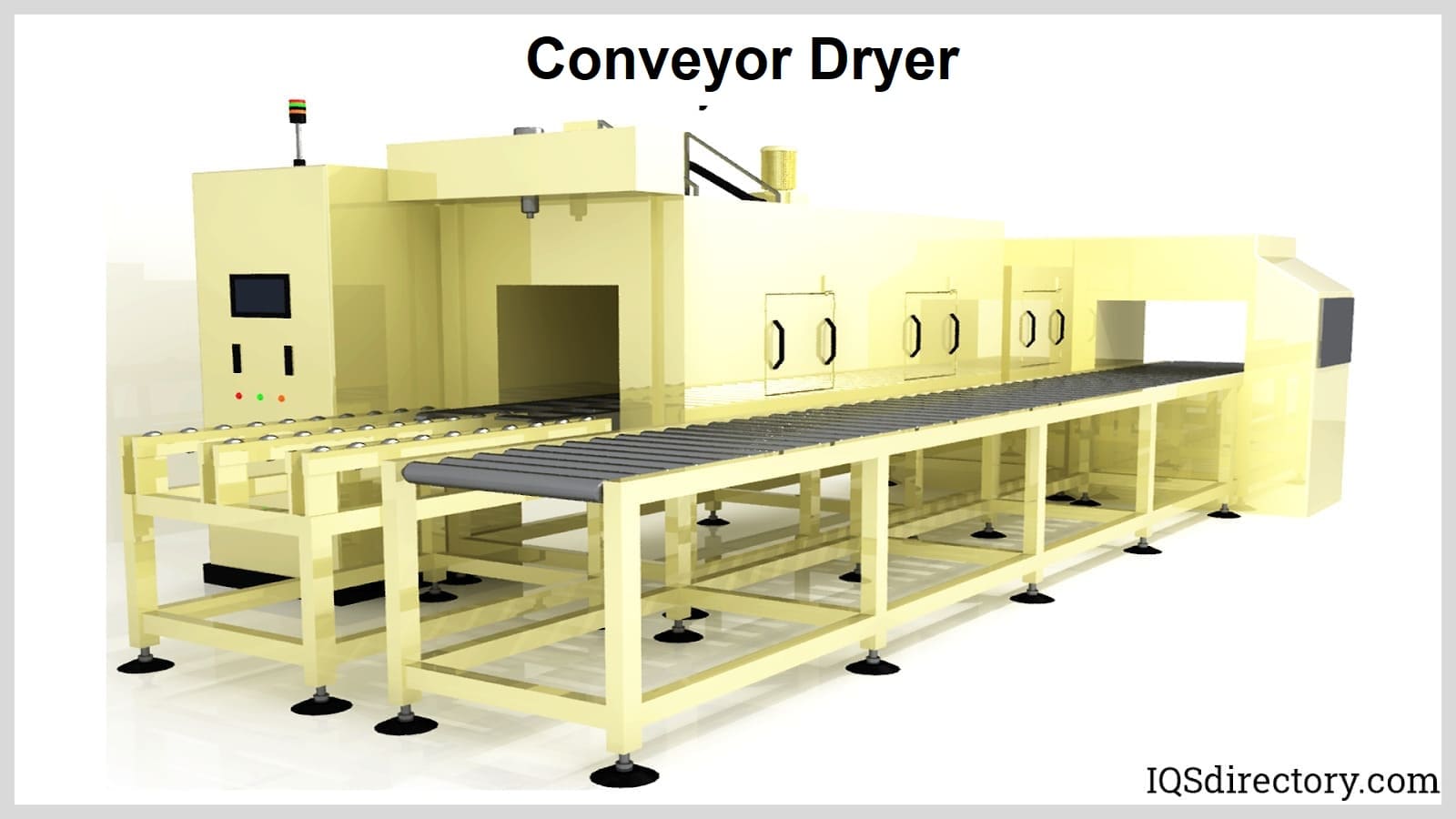

A conveyor dryer is a drying system that utilizes a perforated belt to transfer feed materials through the dryer. This system involves passing hot air with the belt and the product bed before it is reheated and re-circulated. Read More…

Dürr is a leading global supplier of environmental solutions and engineered products tailored to meet customers' industrial process requirements. We offer a complete portfolio of air pollution control technologies and drying and curing systems, including industrial dryers and ovens for roll-to-roll processes, web forming processes and conveyor handling of webs, as well as specialized coating...

The Onix Corporation is a leader in the dryer industry, specializing in rotary dryer & wood combustion systems, dryer control systems, & air pollution control systems. Other areas of expertise are wood fired boilers & industrial consulting on existing rotary dryers. All our equipment is industrial duty 24/7 equipment & carries a hostile environment rating, UL listing & a 3-year warranty.

Dri-Air Industries' expertise is in plastic drying technology. The plastic drying systems we offer problem solve for drying plastic resins, mixing and blending. Our product line includes industrial dryers, desiccant air dryers and hot air dryers. Newly offered is our micro dryer for micro molding machines.

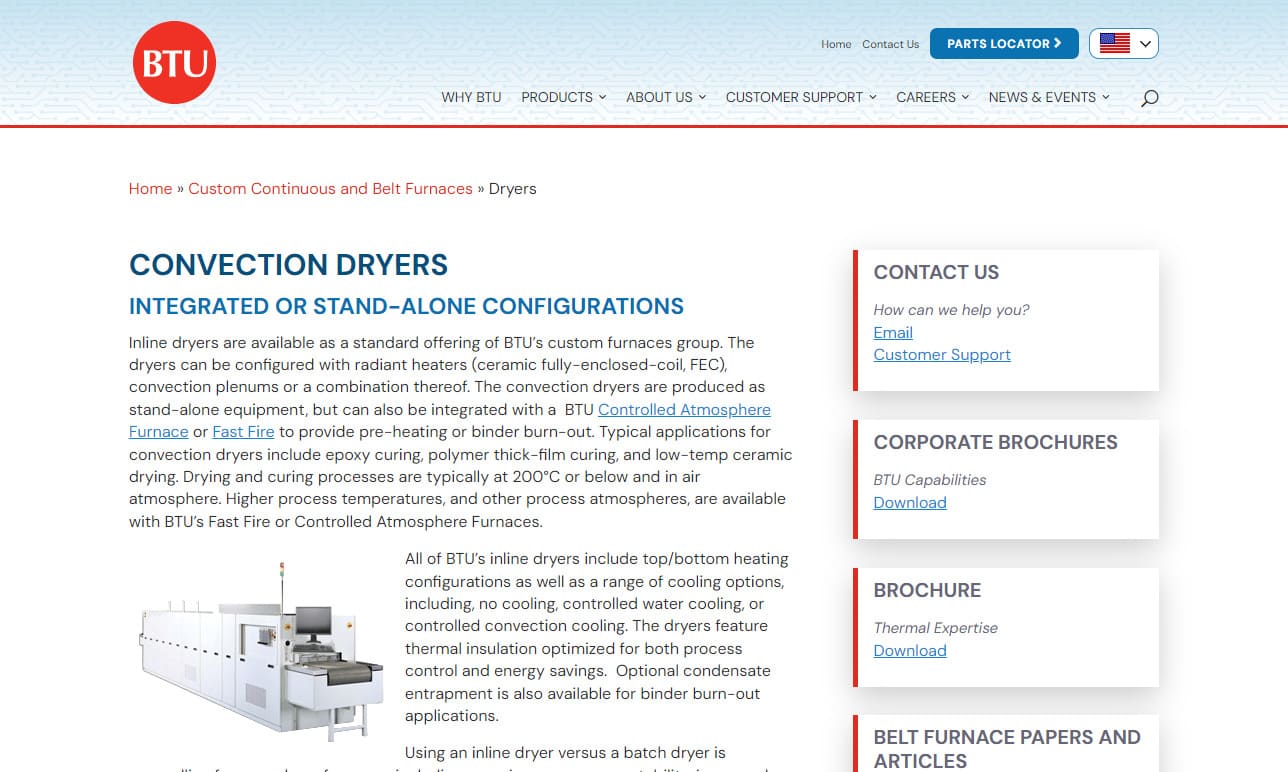

BTU International is a global supplier/manufacturer of thermal processing solutions. Combining our engineering expertise with our acquisition of Radiant Technology Corporation’s product line, we have created the Rapid Thermal Processing (RTP) line of furnaces, specifically designed for solar cell applications such as contact drying/firing and metalization.

More Conveyor Dryer Manufacturers

Conveyor dryers are multi-zoned units and may have separate airflow in successive zones. Furthermore, each zone may utilize a different temperature control and profile. The dryer consists of a central exhaust duct for exhausting saturated or close-to-saturated air. Some types of conveyor dryers are multi-pass units, in which the feed is transferred from one belt to another belt that is below it by gravity. Usually, these types of conveyor dryers are three-pass machines. Furthermore, certain conveyor dryers, like those used in vegetable dehydration, feature an even more complex system. These types of conveyor dryers consist of multiple belts in a line. The feed on these conveyor dryers is transferred from one belt to another.

Types of Conveyor Dryers

Conveyor dryers come in different shapes and sizes and may run on different power sources, depending on the purpose or use.

Gas Dryers

These types of conveyor dryers utilize gas as a heat source. They heat the drying chamber using the convection process. The conveyor dryer applies heat through the system. They gently apply heat, unlike electric dryers. Another benefit of these conveyor dryers is that they are energy-saving compared to their electric counterparts.

Gas conveyor dryers can save up to 30% on energy costs compared to electric conveyor dryers. As a result, gas conveyor dryers may have a high initial purchasing cost. However, the energy savings over time may compensate for the extra cost.

Electric Dryers

These conveyor dryers are an alternative to gas dryers. However, careful considerations must be made when opting for these dryers. For example, manufacturers must check the location and reliability of electrical connections in the facility where they plan to use will use the dryer. Although more expensive to install, gas dryers are more energy-efficient and easier for monitoring temperatures.

Single Conveyor Dryers

On single-pass conveyor dryers, the products travel through the machine only once. The products travel through the machine on a single conveyor on a single-stage machine. These machines offer the advantage that they can be set up with a temperature profile that matches the various phases a material may go through during processing.

Vac Flow

This type of conveyor dryer uses higher air pressure and velocity through a high-resistance conveyor.

Laminar Flow

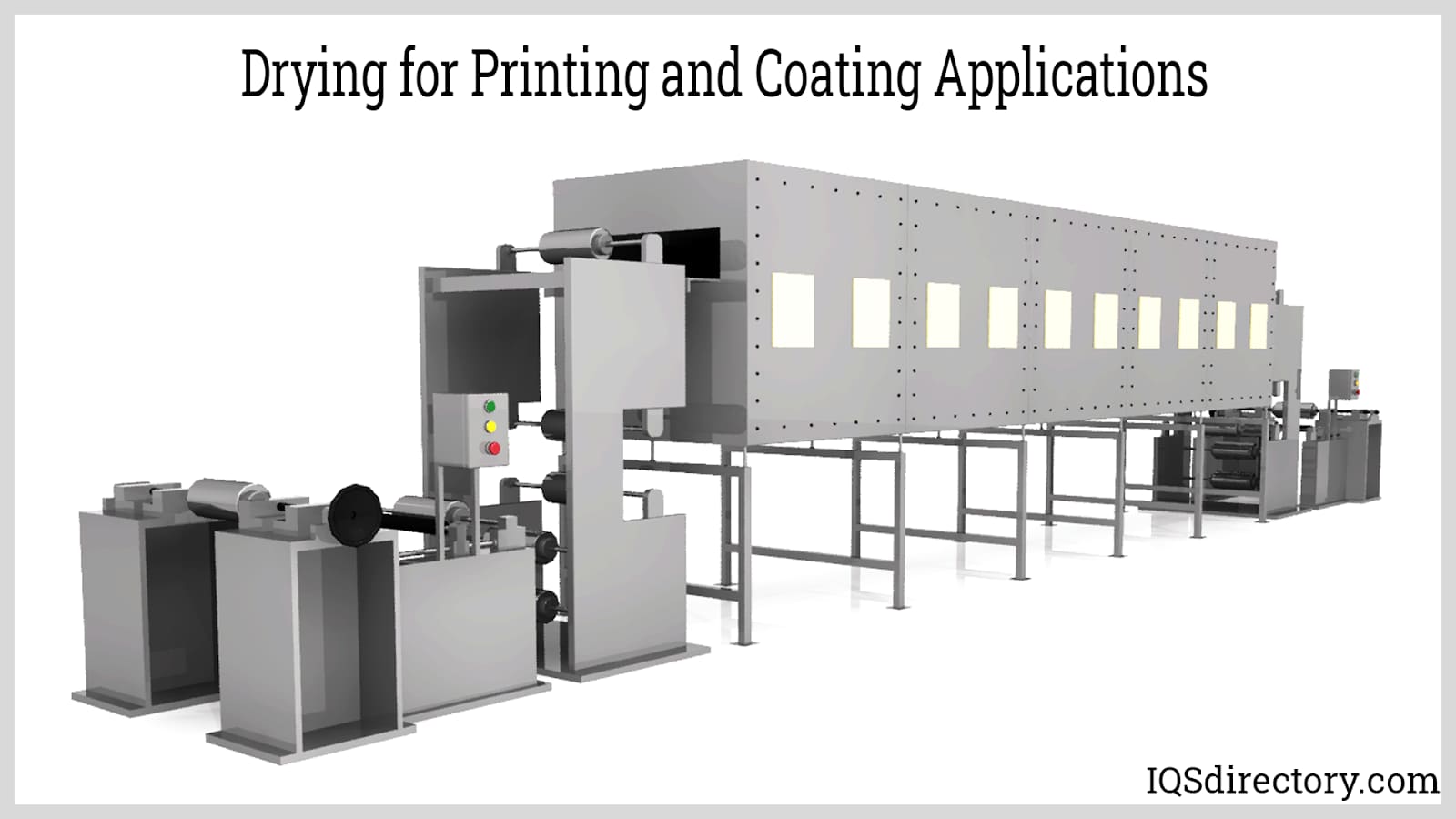

Laminar flow conveyor dryers are used to dry sheet products that have undergone a coating process. This device is appropriate for drying coarse materials like seeds, extruded goods, pelletized plastic raw materials, etc.

With variable speeds and a specified layer thickness, this device may operate as a drier or a continuous, automated vertical cooler. It is a highly useful addition to an existing system or production line since laminar flow conveyors can adjust speed and temperature.

Multistage

Multistage conveyor dryers offer the added advantage of multi-staging. On this conveyor dryer type, the material or product is transferred from one conveyor to the other.

In turn, it will re-orient the product or material, thus allowing the use of deeper beds later in the process and making more effective use of the space available. Multistage conveyor dryers are more suited for very large tonnage machines.

Applications of Conveyor Dryers

- Conveyor dryers are used for drying metal materials that have been put through the coating process. These materials include painted mild steel, stainless steel, and other materials.

- They are also used to dry printed T-shirts, hoodies, and other garments.

Benefits of Conveyor Dryers

- Conveyor dryers are very good for heat-sensitive products and products that require long drying times.

- They have very close contact with air or gas streams.

- Conveyor dryers are very efficient because they recycle processed air.

- The multiple zones of conveyor dryers offer flexibility for controlling temperature and processes.

- There is an excellent transfer of energy with conveyor dryers.

- Conveyor dryers are capable of varying flows between zones.

- Conveyor dryers provide gentle handling of products.

- Conveyor dryers are self-contained with distributed foundation loading.

- Conveyor dryer units can also have integral cooling sections.

Drawbacks of Conveyor Dryers

- Conveyor units with high temperatures can be troublesome.

- Belt tracking, the ability to maintain the belt's path, can be a problem.

- The heater can clog while items are being transferred between belts or zones.

- The belt may clog. Therefore, it requires frequent cleaning.

- Conveyor dryers are involved with the loss of an item's very small particles that occur through perforations on the belt.

Selecting the Right Conveyor Dryer Manufacturer

To make sure you have the most constructive outcome when purchasing a conveyor dryer from a conveyor dryer manufacturer, it is important to compare several companies using our directory of conveyor dryer manufacturers. Each conveyor dryer manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each conveyor dryer business website using our patented website previewer for an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple conveyor dryer businesses with the same form.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services